The 4 stages of MGI Stampings®

Rather than just a company, we are a motivated work team that seeks to be a reference fro both the technical and the human aspects of our field. Therefore we link out training and career paths to quality indicators, to deliver precisioón productsin a service environment.

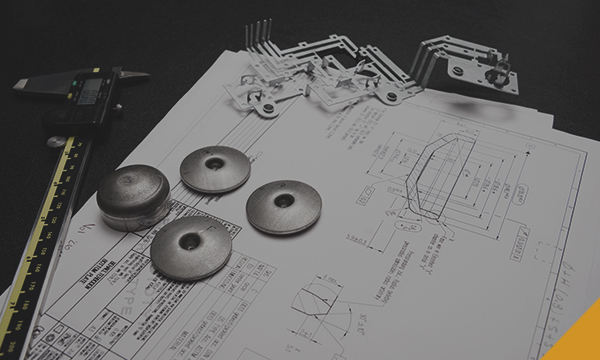

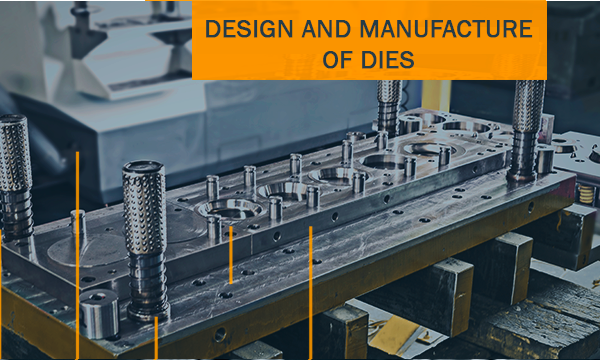

Is a company dedicated to the manufacturing oft stampings, as well as the design and manufacture of dies.

“We are company whose people and equipoment enable us to provide timely quality service at the best price along with the flexibility to handle parts at high and low volumes”.

We are a company whose people and equipment enable us to provide timely quality service at the best price along with the flexibility to handle parts at high and low volumes

In 1989 he company was founded as a tool-room, and initially manufactured devices, fixtures, dies, etc.

In 1993 the company initiated the production of metal stampings in addition to the design and manufacture of tooling.

In 1999 we started producing parts to the automotive industry, our first automotive customer was ZF Sachs(shock absorber manufacturer).

Later in 2011 we started production at new ,400 m2s factory, which is where we currently hold our operations.

All production was transferred to this new production plant of 2,400 m2 by late 2012.

Solutions

VIEW MORE

VIEW MORE

Quality

We are en ISO / TS 16949-2009 certified, and since 2005 in ISO 9001.

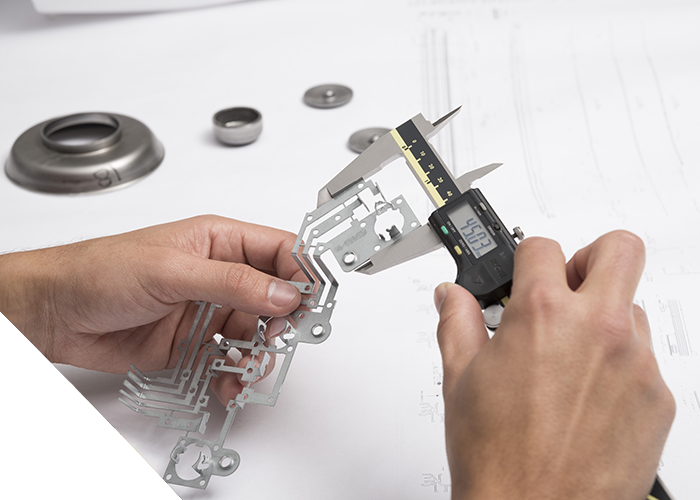

Supporting quality, we have an area of metrology with measuring equipment such as calipers micrometers, a durometer, laser micrometer, a CMM, among others.

We certify the quality of our finished products, by using inspection gauges and the use of statistical control.

Customers

Contact